-

All Categories

- 3D Prototyping

- Gift & Souvenirs

- Home Decor

- Jewelry Moldings

- Medical Devices

- Miscellaneous

- UV Resin

Jewelry & Investment Casting

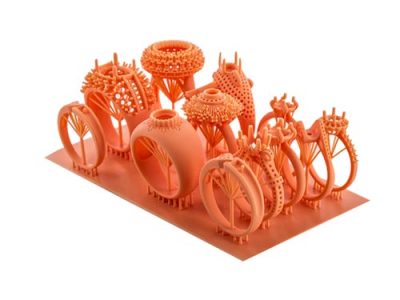

In the traditional jewelry-making process, jewelers must carve out intricate and detailed patterns in wax by handcrafting. These are time-consuming techniques that are prone to human errors. One mistake can force the entire process to start from scratch. 3D printing of jewellery patterns is the latest state of the art method to create wax patterns of any intricate design.

We are a leading choice among goldsmith jewelers, and custom manufacturers for 3D printing jewelry patterns for casting. Our technology and materials offer superior detail, precision and a smooth surface finish that requires less finishing. We use imported high quality photosensitive resin which can manufacture master patterns with very intricate designs-which are impossible to craft by hand.

3D printed wax patterns are then placed into a mold cavity and poured with investment casting, a plaster that surrounds the jewelry patterns and hardens. 3D printed wax masters are burnt out in a muffle furnace in a thermal cycle to the maximum temperature of 730-750*C thus creating a mold cavity in the hardened plaster. Jewelry pieces are cast with metals such as gold, silver, bronze to create the final product.

Please upload your design in. stl /.obj file and get the quote within 24 hours.

Price Rs 300/- to Rs 5000/-

Minimum Order: 1No

Custom Jewellery

You can select design from any catalog & upload your stl/obj file at our site. We shall make a hard plastic piece for your review

You can select design from any catalog & upload your JPEG file at our site. We shall design and make a hard plastic piece for your review.

You can select designs from the websites such as those given below and send It to us.

We shall make a hard plastic piece for you for your review.

Once you are happy with your choice of design, you may talk to your jeweler and we shall create a wax pattern for metal casting of the jewelry piece by your jeweler.

Price Rs 300/- to Rs 5000/-

Minimum Order: 1No

Rubber Molds for Jewelry Casting

Rubber molding is an important part of the jewelry-making process and is especially suitable for creating small, intricate jewelry pieces such as rings and pendants. By creating rubber molds, jewellery designers can repeatedly create the perfect jewelry piece in large quantities without the need for making wax patterns again and again.

We make master patterns for rubber molding with 3D printing for faster production and lower costs. Use our masters to create molds that produce wax patterns in quantity for investment casting in gold, silver, copper & bronze. We use special resins which can sustain higher temperature required for vulcanized rubber molding

Price Rs 300/- to Rs 5000/-

Minimum Order: 1No

Lost Wax Investment Casting Patterns for Industrial Components

No need of costly tooling for injection molding of your wax patterns

Need not to wait for weeks and months for manufacturing tooling for wax patterns

Now you can directly get 3D printed wax patterns on a very short notice for investment casting into mechanical components.

More complex designs can be created which are not possible by machined tooling

Wax Evaporation/ meltdown Temperature: 730*C to 750*C

Residual Ash: 0.05%

Max Dimension: 100 mm

Minimum Hole Diameter: 2 mm

Minimum Wall Thickness: 1 mm

Accuracy: +- .10 mm

Upload your designs in stl/ obj files for your prototyping needs for mechanical components in investment castings or for small batch production

Price: Rs 200/- to Rs 7000/-

Minimum Order: 1No