-

All Categories

- 3D Prototyping

- Gift & Souvenirs

- Home Decor

- Jewelry Moldings

- Medical Devices

- Miscellaneous

- UV Resin

Functional Parts & Tooling

3D printing can enhance your journey from concept to reality, it is inexpensive, and the benefits totally outweigh the cost.

If you have a 3D CAD model already, a drawing or perhaps just a sketch on a piece of paper, contact us and see how we can provide you with an accurate 3d model to help you move your ideas forward.

If you would like us to print your 3D model, please send us a copy in any of the following formats:

.STEP, .STL or .OBJ.

If you have a 2D drawing that you would like to printed in 3D, please send us a copy and we will give you a price for modelling and printing.

Custom Designed Poly Urethane (PU) Seals & Gaskets

PU (Urethane) is the solution when the gasket or seal needs to be soft like rubber or hard like plastic but endure environments neither rubber or plastic can survive. The material characteristics of polyurethane make it better resistant to abrasions, cuts, cracking, oil, grease, chemicals, high impact, and heavy loads. PU is also resistant to greases, oils, fats, moderate chemicals, hydrocarbons and Ozone. It is a suitable material for temperatures up to 80 *C.

We manufacture custom designed seals, gaskets, hydraulic chevron packings, O rings hydraulic seals etc. for medium pressure applications on resin printers & on FDM printers depending upon the accuracy requirements. We can achieve dimension tolerances of +-0.05 mm on resin printers & +-0.2 mm on FDM printers. Hardness of PU seals & gaskets is in the range of shore 65 A to shore 95 A.

Any intricate design can be manufactured.

Polyurethane Rubber O-Rings Features:

- Good hydraulic oil and gasoline resistance

- Resistant to pure aliphatic hydrocarbons (propane, butane, fuel)

- Resistance to mineral and silicone oils and greases

- Resistant to water, oxygen, ozone and aging

- Excellent tear and abrasion resistance

- Available in multiple types and compounds to meet performance and cost requirements

Polyurethane Rubber O-Rings Limitations:

- Not compatible with acids, ketones, esters, ethers, alcohols, glycols

- Hot water, steam, alkalis and amines

Price Rs 200/- to Rs 10000/-

Minimum Order: 1 Pcs

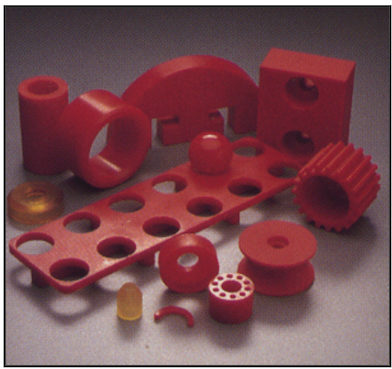

Polyurethane Components

We can 3 D print any mechanical component made from molded and machined polyurethanes to a dimensional accuracy of +-.05 mm and maximum piece weight of 50 grams on our highly accurate resin printers. We also manufacture in higher weights up to 250 grams on FDM printers up to dimensional accuracy of +-.20 mm. It can be impellers, bushes, vibration pads, couplings, suction cups etc.

Due to unique capabilities of FDM 3D printers, we can reduce weight of the parts without sacrificing the strength by 30 %.

Price Rs 200/- to Rs 10000/-

Minimum Order: 1 No

Jigs & Fixtures

Jigs and Fixtures are widely used in manufacturing for accuracy, precision, reliability and interchangeability of finished parts. 3D Printed Jigs & Fixtures are slowly substituting CNC machined ones, more so when irregular and complex shapes are involved, and parts are small. It saves on time and cost.

We use FDM 3D printers that build plastic parts layer-by-layer using data from computer-aided design (CAD) files in stl and obj format. By using FDM, the traditional fabrication process is substantially simplified; tool-making becomes less expensive and less time-consuming. FDM also makes it practical to produce jigs and fixtures for operations where they have not been previously feasible due to cost or design complexities when produced with traditional manufacturing methods. These are also suitable in medical applications when bio-compatible materials are used.

Materials we use: Polycarbonate, ABS, PC-ABS, Nylon and CF Nylon

Maximum Size: 230 mm

Dimensional Accuracy: +-0.2 mm

Max Application temperature: 100*C

Price Rs 500/- to Rs 10000/-

Minimum Order: 1 No

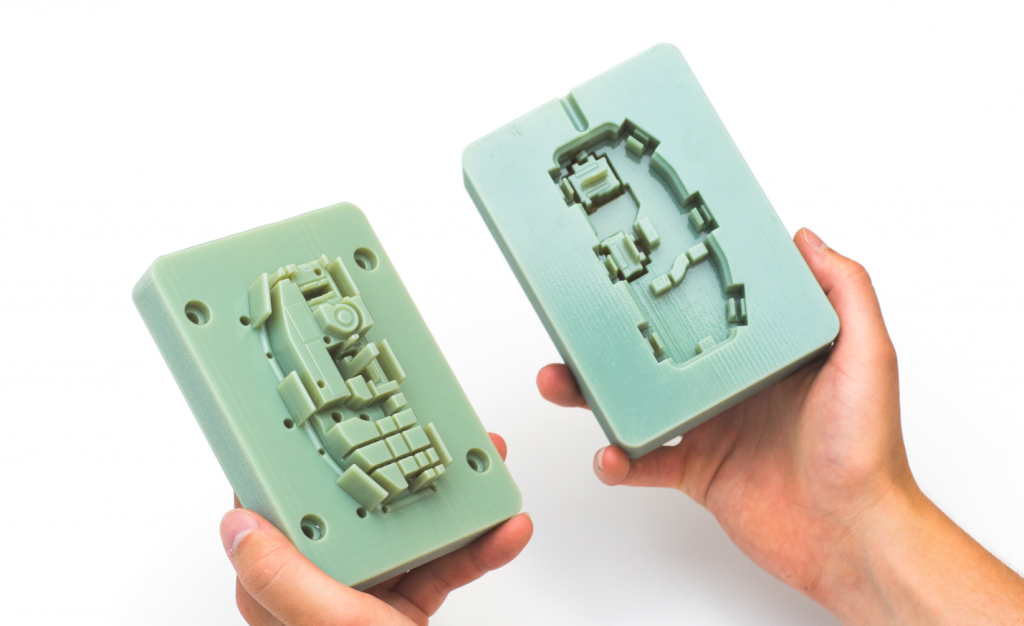

Injection Molds for Low production

Injection Molding the most common method for mass producing plastic parts. It is ideal manufacturing method for producing rapidly very large numbers of identical parts with tight tolerances. The high initial setup costs associated with injection molding make this technology cost-effective only at high volumes. A typical run can involve the production of thousands or sometimes millions of components.

3D printing of molds by using SLA technology has made it possible to manufacture intricate plastic parts in small volumes, mainly 10 to 100 pieces. Small volumes manufacturing using machined tooling is not feasible due to high cost involved in making injection molding dies.

We use high deflection resistant temperature resins to manufacture molds with the following broad properties:

Heat Deflection Temperature: Above 200*C

Flexural Modulus: Above 2.2 GPa

Minimum Detail Size: 0.30 mm

Maximum Size: 150 mm

Price Rs 1500/- to Rs 15000/-

Minimum Order: 1 No

3D Printed Functional and End Use Parts

Functional prototypes offer a way to test designs before manufacturing them at scale. Functional prototyping happens in the design stage of manufacturing. Each time a design is changed, more resources must be dedicated to producing another functional part or assembly.an replace

We supply printed functional parts in a wide variety of materials. Time to bring the product to market from design phase is greatly reduced thus economizing the whole cycle.

3d printed parts from Cf Nylon and PC _ABS filament can replace components manufactured from Aluminum and its alloys for short production runs

Traditional manufacturing imposes design limitations because of constrains imposed by machining technologies and tooling. Designer enjoys complete flexibility in designing the parts with any intricate contours and inbuilt supports and hollow profiles when manufactured by 3D printing. 3D printing technologies allow reduction in weight by more than 30 % without sacrificing the strength.

Material: Nylon, CF Nylon, ABS, ASA, PETG, PC, PC-ABS,

Minimum wall thickness: 1 mm

Minimum hole: 2 mm

Maximum Size: 230 mm

Price Rs 500/- to Rs 6000/-

Minimum Order: 1 No